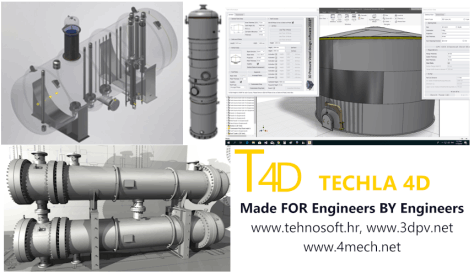

Software FOR Engineers, made BY Engineers!

Simple, Fast and Accurate

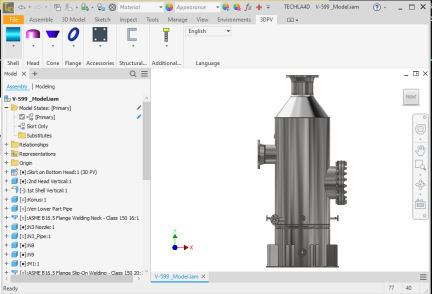

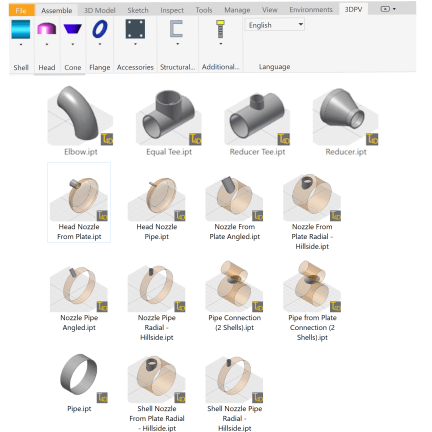

T4D™ enables the rapid configuration and detailing of pressure equipment and storage tanks automating the generation of 3D geometry models, elevation and layout drawings, fabrication and assembly drawings, production component lists and bill of material.

It offers advanced tool for the accurate production of 3D digital prototype and workshop drawings deliverables of pressure vessels or any type of equipment.

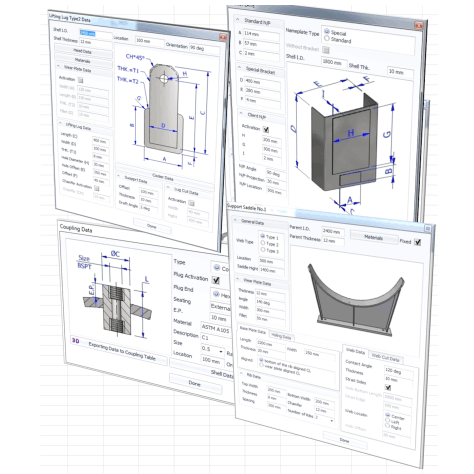

Without and need for third party application, T4D™ delivers significant time savings over existing 3D/2D CAD modeling and drafting methods while reduces errors and engineering time using automated input forms.